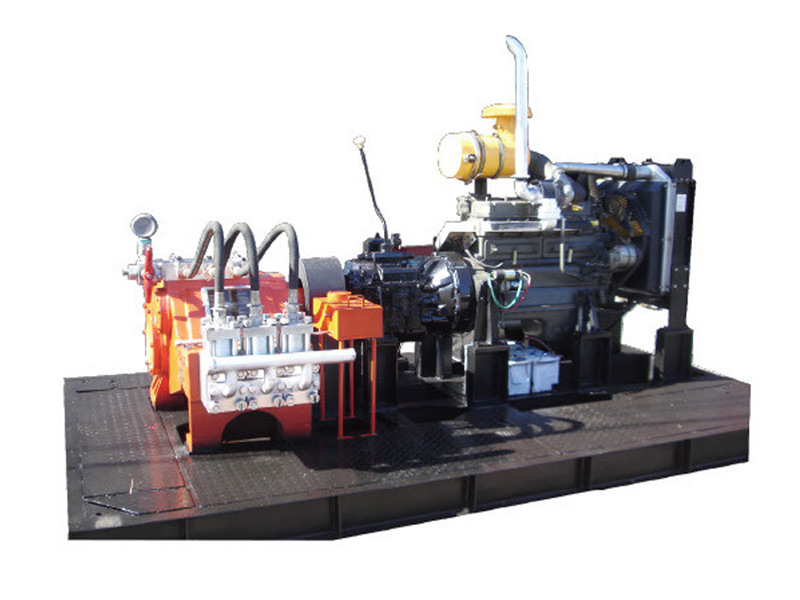

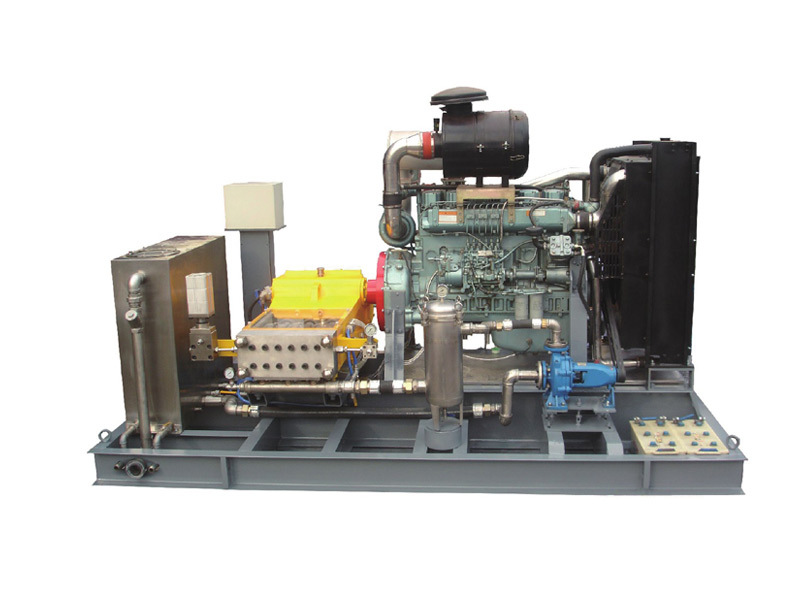

Double liquid low pressure grouting pump XPB-10

Keywords:

Classification:

Introduce

A double liquid low pressure grouting pump is an essential piece of equipment used in construction and geotechnical engineering for delivering grout into the ground at lower pressures. This pump plays a vital role in various applications, including soil improvement, foundation stabilization, and repairing concrete structures.

The double liquid low pressure grouting pump is designed to handle the injection of grout consisting of two components: a base material and an activator or hardener. By combining these components at the point of injection, the pump ensures proper mixing and activation, resulting in an effective grouting process that enhances soil properties and strengthens foundations.

This type of grouting pump operates at lower pressures compared to high-pressure pumps, making it suitable for applications where gentler treatment of the soil or structure is required. The controlled delivery of grout at lower pressures helps minimize disturbance to surrounding soil and structures, making it ideal for delicate or sensitive projects.

The versatility and precision of the double liquid low pressure grouting pump make it a valuable tool in a wide range of construction and geotechnical tasks. Whether used for void filling, crack repair, or soil stabilization, this pump ensures efficient and reliable grout injection, contributing to the success and longevity of various engineering projects.

Double-(III) liquid pump is a new product developed by our company on the basis of high-pressure grouting pump in order to meet the special grouting requirements. Each working cylinder adopts the mode of separate liquid inlet and separate liquid discharge to meet the requirements of users for various liquid grouting. A one-way valve is installed at the front end of each liquid discharge pipeline to prevent different liquids from mixing in the pump and effectively prevent the pump from working normally due to too fast solidification. The one-way valve is set at the nearest to the working face, conducive to safe use. The working principle of the three (double) liquid pump is exactly the same as that of the high-pressure plunger pump. The difference is that the inlet and discharge methods, the different media bring about changes in the sealing method and the material changes caused by the need for corrosion resistance.

All kinds of pump type mud pumps in our company can be converted into three liquid pumps. The parameters shown in the product sample are only one of the models as an example. Users are welcome to order according to the parameter requirements.

Performance parameter table

|

Maximum motor speed |

1300r/min |

Plunger stroke |

85mm |

|||

|

theoretical flow |

Motor power (kW) |

Plunger Diameter mm |

||||

|

11 |

15 |

18.5 |

22 |

|||

|

M3/h |

L/min |

Rated discharge pressure (kgf/cm²) |

||||

|

9.6 |

160 |

25 |

35 |

45 |

52 |

50 |

|

7.8 |

130 |

32 |

45 |

55 |

65 |

45 |

|

6 |

100 |

46 |

55 |

70 |

85 |

40 |

|

5.4 |

90 |

50 |

65 |

80 |

95 |

38 |

|

4.8 |

80 |

58 |

80 |

95 |

// |

35 |

|

3.3 |

55 |

80 |

// |

// |

// |

30 |

Note: The above parameters are theoretical data when the specific gravity of the medium is 1.0.

Application

Machinery manufacturing

Mining

Municipal

Aviation

Related products

Product Consultation