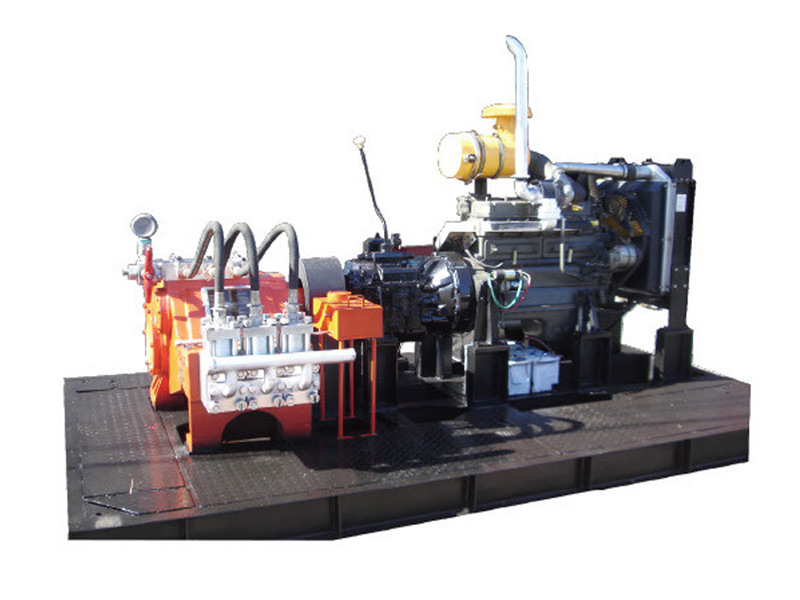

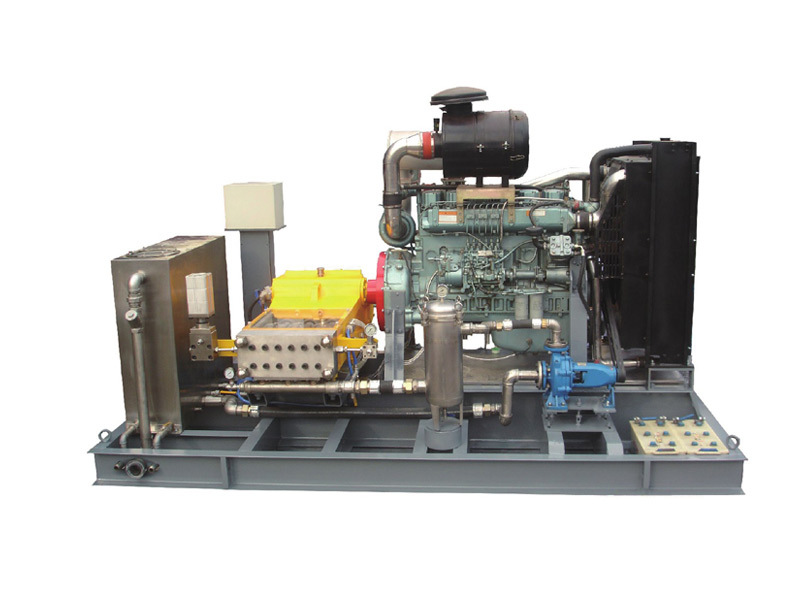

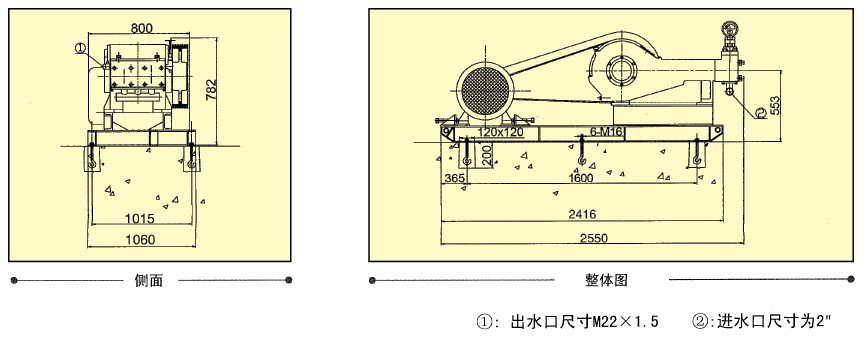

High Pressure Plunger Pump 3S-15 Series

Keywords:

Classification:

Introduce

A high pressure plunger pump is a specialized hydraulic pump designed to generate and maintain significantly elevated pressure levels for industrial and commercial applications. These pumps utilize reciprocating plungers to create high pressures, typically exceeding 1000 psi, making them suitable for tasks such as car washing, pressure cleaning, water blasting, and other high-pressure fluid transfer operations. The compact design and efficient operation of high pressure plunger pumps ensure reliable and precise pressure control across a variety of settings.

High pressure plunger pumps play a crucial role in industries that require consistent and efficient high-pressure fluid transfer capabilities. With the ability to deliver intense pressure with minimal pulsation, these pumps are ideal for applications that demand precise and uniform output, such as water jet cutting, industrial cleaning, and chemical injection systems. The robust construction and advanced sealing technology of high pressure plunger pumps guarantee durability and sustained performance in harsh operational environments.

Operators and maintenance professionals value the reliability, durability, and flexibility of high pressure plunger pumps in diverse industrial and commercial settings. These pumps are engineered with features like adjustable pressure settings, easy maintenance access, and materials resistant to corrosion to ensure smooth operation and extended service life. Whether utilized in manufacturing facilities, construction sites, or agricultural operations, high pressure plunger pumps provide the essential high-pressure fluid transfer capabilities required to optimize performance and productivity in a range of applications.

3S-15 high-pressure water pump is a new product specially developed and developed by our company for users who cannot stop for a long time.

The power end of this product adopts integral rolling bearings, gearless transmission, suitable for long-term operation, low temperature rise, low noise, in the same level of products, is the most cost-effective a new type of replacement products.

Performance parameter table

|

Input shaft speed |

1480r/min |

Plunger stroke |

80mm |

|||||

|

theoretical flow |

Motor power (kW) |

Plunger Diameter mm |

||||||

|

18.5 |

22 |

30 |

37 |

45 |

55 |

|||

|

M³/h |

L/min |

Rated discharge pressure (MPa) |

||||||

|

6.60 |

110 |

7.2 |

9.1 |

14.1 |

17.4 |

21 |

// |

40 |

|

5.8 M³/h 98L/min |

||||||||

|

8.40 |

140 |

5.6 |

7.2 |

11.1 |

13.7 |

16.7 |

20 |

45 |

|

7.4 M³/h 124L/min |

||||||||

|

10.3 |

173 |

4.5 |

5.8 |

8.9 |

11.0 |

13.4 |

16 |

50 |

|

9.2 M³/h 154L/min |

||||||||

|

12.5 |

209 |

3.7 |

4.8 |

7.4 |

9.1 |

11.1 |

13 |

55 |

|

11 M³/h 186L/min |

||||||||

|

14.9 |

249 |

3.1 |

4.0 |

6.2 |

7.6 |

9.3 |

11 |

60 |

|

13M³/h 22L/min |

||||||||

Note: The above parameters are theoretical data with a specific gravity of 1.0

Application

Machinery manufacturing

Mining

Municipal

Aviation

Related products

Product Consultation